NEWMATT develops Structural Health Monitoring (SHM) procedures through the use of laser scanning vibrometry and innovative sensors/actuators. Scanning laser scanner vibrometers are used to detect the dynamic response of structural components subject to wave propagation, through space-time maps of vibration velocities. The adoption of suitable filtering techniques, which separate incident and reflected waves, allows us to isolate local defects due to cracks and delamination, and diffuse damage due to porosity and wrinkling.

Advanced techniques for non-destructive Structural Health Monitoring

Structural Health Monitoring through laser scanning vibrometry.

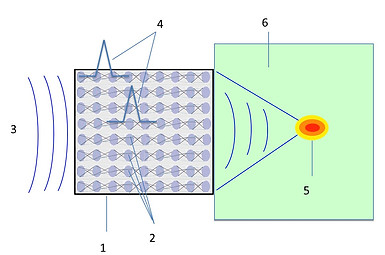

We also design innovative sensors/actuators through periodic arrays of tensegrity structures, freestanding or embedded in a matrix. Such units are controlled by embedding piezoelectric layers in the junction elements, connected by wires to transfer data, and/or equipping the bars and strings with strain gauges or other displacement/stress sensors. Our sensors/actuators are able to transform a given incident acoustic signal into either a single solitary pulse or trains of solitary pulses with tunable compact support and arbitrarily large amplitude, which can travel finite distances in the host medium.

Tensegrity actuator-sensor systems are used by NEWMATT to detect the mechanical properties and/or the presence of damage in materials and structures through closed-loop identification procedures. The compact and transient pulses generated by tensegrity actuators can also be used as acoustic lenses with exceptional focusing properties, noninvasive scalpels to accurately target tumors in hyperthermia applications, and for lithotripsy applications.

Schematic diagrams representing the use of a tensegrity material as an acoustic lens.